Metal Fabrication

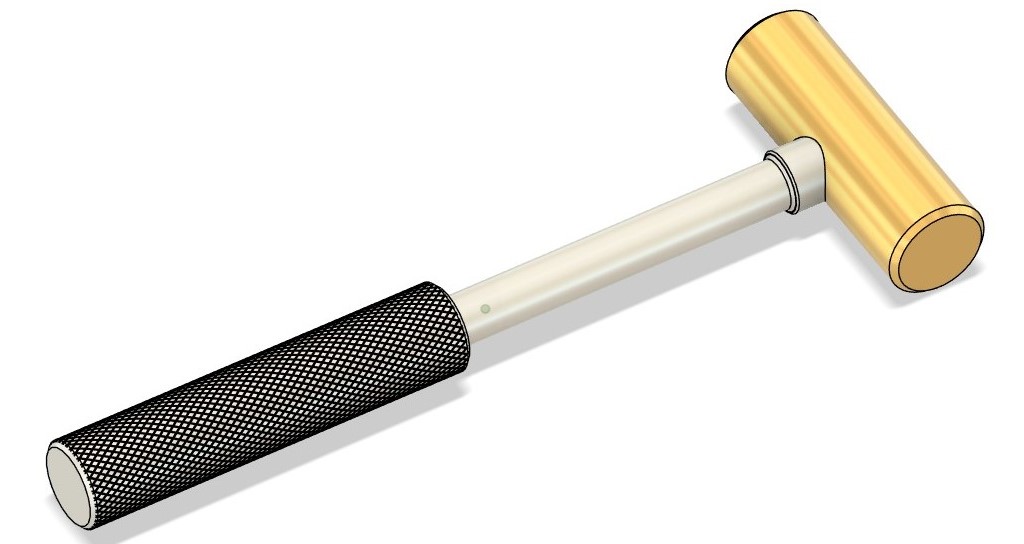

Machine Shop: Make a Hammer

Make a machinist's hammer to keep with aluminum and brass as you learn basic metal machining techniques.

Member$215.00 (any noted materials fee included) |

Guest$264.00 (any noted materials fee included) |

Tuition Assistance and Other Policies

Meeting Times

- Tue, 3/10/2026 6:00 PM - 9:00 PM

- Thur, 3/12/2026 6:00 PM - 9:00 PM

Tue, 3/10/2026 - Thur, 3/12/2026

About

Machining operations covered include basic metal turning, external thread cutting, knurling, chamfering, cutting off, milling a flat on a round work piece, drilling, and tapping threads.

The hammer, which is yours to keep, has a brass head and is useful as a "positioning" hammer.

Details

Before the class, you should view the following four YouTube videos by "That Lazy Machinist" on how to make this type of hammer: Part 1, Part 2, Part 3, Part 4.

Materials

- A $30 materials fee, included in the price of the class, includes everything you'll need to make one hammer.

- If you want a hammer head other than brass that's 1.25 inches in diameter, bring the material to class.

Prerequisites

Class Policies

- Ages 14 and up are welcome.

- You must wear shoes or boots with closed toes and heels. Tie back long hair. Avoid loose-fitting clothing and jewelry, and roll up sleeves.

BARN Policies

- View BARN's Cancellation and Refund Policy.

- Tuition Assistance is available. Fill out the application before registering.

- BARN is committed to accessibility. We try to make accommodations when requested; the earlier you contact us, the more likely we can help. Fill out the Accommodation Request Form before any class for which you require an accommodation. Email accessibility@bainbridgebarn.org if you have any questions.

- Sensory Statement: Makerspaces like BARN can be noisy and cluttered, smell strongly, and have bright or flickering lights. BARN is not an allergen-free facility. If you have concerns, please email info@bainbridgebarn.org.

Instructors or Guides

Andy Dupree

Andy moved to the Northwest, working for Microsoft before turning to management and leadership consulting. Over the last few years, he has been honing his skills as a machinist and now focuses on tool making and building small steam engines.

Allen Miller

Follow Us